What makes a brand? Each brand has a different history and story; where they began and where they are now.

This is the story of 3 (in our opinion) of the best suppliers of military footwear, Let’s look at the brands that sell well for us, these include:

- AKU

- ALTBERG

- SALOMON

It is previously mentioned that we find it hard to choose ‘the best’ as these three brands are top sellers and have top-tier qualities.

The qualities that make these brands so reliable are:

- Durability

- Comfort

- Waterproof/ water repellent

- Quality fabric

- Diverse styles to suit different needs

Let’s rewind for a moment and look into their company’s backgrounds.

AKU

( History – Aku )

The history of AKU begins in a shoemaker’s workshop in a district of Montebelluna, the small Venetian town that in over a century has built and spread the myth of Italian sports footwear all over the world.

Galliano Bordin, founder of the company, is the son of shoemakers and since he was a child he acquired experience first in the repair and then in the construction of footwear. Almost in every family of the small Venetian town, hides are cut, uppers are sewn, soles are attached. Almost everyone, in one way or another, is part of this production specialization that generates artisan workshops and small businesses destined over time to become the most prestigious brands at an international level in various sports fields, but in particular for mountaineering, the trekking, alpine skiing and cross-country skiing.

The name AKU

From Scandinavia to the Pacific Ocean to the Alps:

a legendary adventure

We are often asked about the origin and meaning of the name AKU.

AKU AKU is the name of a benevolent spirit told in one of the many legends that populate the imagination of the natives of Easter Island. A benevolent and wise spirit that protects the earth and its inhabitants, mentioned in the book The Secrets of Easter Island by the great Norwegian adventurer Thor Heyerdahl.

The idea of using this name as a brand dates back to the early 90s when Galliano Bordin, founder of the company, at the beginning of the export to Europe of the first trekking shoes, had to decide to abandon the first DINSPORT company name and logo, in contrast to the registered DIN trademark of the Deutsch Institut fur Normung.

The idea of using AKU, a short and easy to remember name, with a meaning so close to the sensitivity of the company and future users of its products, was then liked.

ALTBERG

(The Beginning of Altberg | The Altberg Factory | Alt-Berg )

The old Richmond shoe factory closed in 1989, 320 people were made redundant… it was a sad day. For the previous ten years it had been constantly on the news that ’Globalisation’ was the new way forward, and our type of ’low tech’ manufacturing was considered to be no longer desirable in England. We were told that the future was in financial and service industries. My working life had been making shoes, and I had always enjoyed ‘making things’… so that’s how in 1989 Altberg was started. Most people thought it was completely mad, but I didn’t really know anything else…

Group outside the old factory – Altberg summer 1992

Group inside the factory – Altberg Christmas 1990

The first five years were incredibly difficult… we had no money, no orders and no materials. Although I knew about boot making I had no experience whatsoever about how to run a business!! There were many problems, and on more than one occasion we thought closure was inevitable… but always at the last minute, a little bit of luck came along and so we kept going.

After five long years it looked like we might survive, orders were more regular and we even had a waiting list for some of our most popular boots…

In 2001 I had the opportunity to start a second factory in Italy… in an area where bootmaking had always remained strong, and where bootmaking skills were still being passed on from one generation to the next… it was just like it used to be 20 years before in England. The factory was close to tanneries and companies that made lasts, linings, soles, ‘D’ rings, everything needed for making boots, components and materials that were no longer available in England. This helped not only in Italy, but also in Richmond… and I was able to begin to develop new ranges of boots in Richmond for hiking, military and police.

I’m now 70 years old (2017), and I still work everyday in my factory in Richmond, and one week each month in the factory in Italy… and now I’m working with the next generation. We are a small group of people, but we still work in the old way and they are learning in the same way that I learned and they will carry our bootmaking forward.

SALOMON

1947- Founding of the company François Salomon et fils

As the holder of an advanced diploma, Georges Salomon has no intention of acceding to his father’s wish to become a teacher. He expresses a desire to join his father’s business. At the time, the small workshop based in historic Annecy produces beveled ski edges, for which a patent is filed (Patent No. 948 013 of 28 May 1947). From then on, Georges becomes interested in the development of skiing as a leisure pursuit in the neighboring mountain villages, which are installing ski lifts.

1957- Launch of the “skade” safety toe piece

The champion skier Emile Allais agrees to lend his name to this toe piece developed by Georges Salomon, which combines a twisting motion with a forward motion. (Patent No. 1 130 484 of 7 May 1955). Two years later, the first binding – the Lift – replaces the traditional leather straps. This first safety binding is a success. The company recruits, expands, and develops new products.

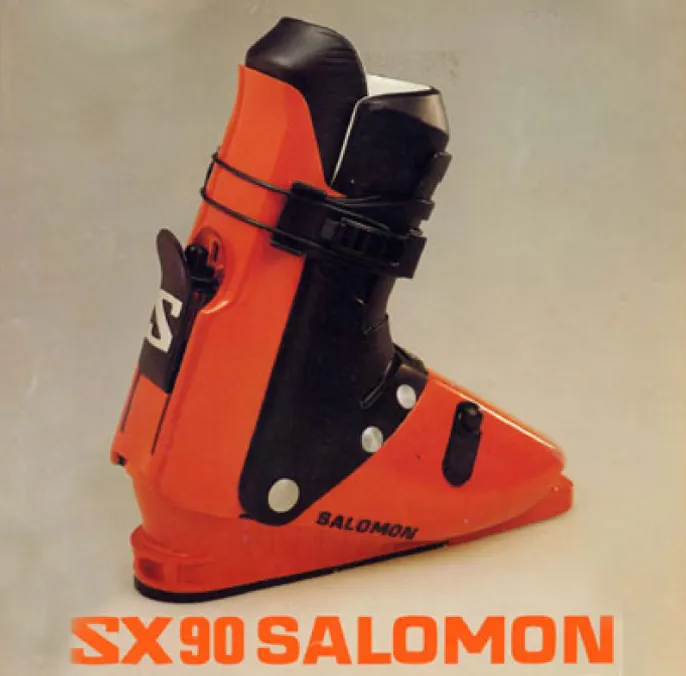

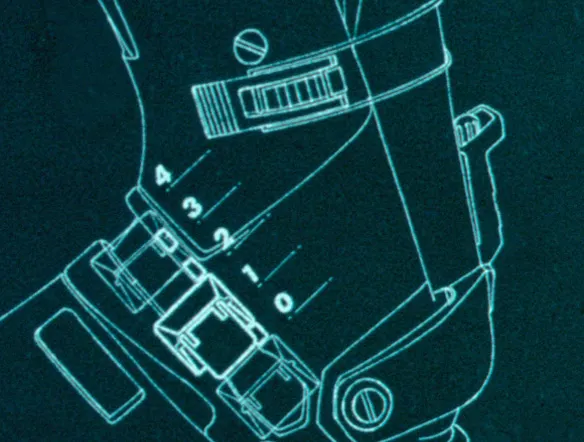

1979- Launch of Salomon’s first ski boot: the SX90

It is the first boot with rear entry and heel retention. Salomon commissioned the TGV designer, Roger Tallon, to design it. To manufacture it, the Annecy-based company mastered the process of plastic molding and multi-injection of technical components, as well as the use of special fabrics and composite materials. Initially launched in France and then worldwide in the following year: the famous orange boot is a dazzling success.

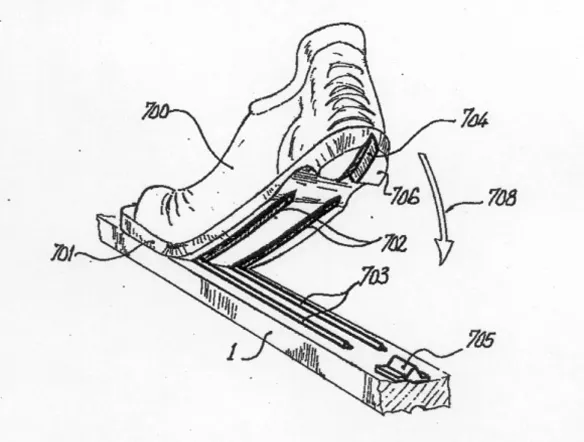

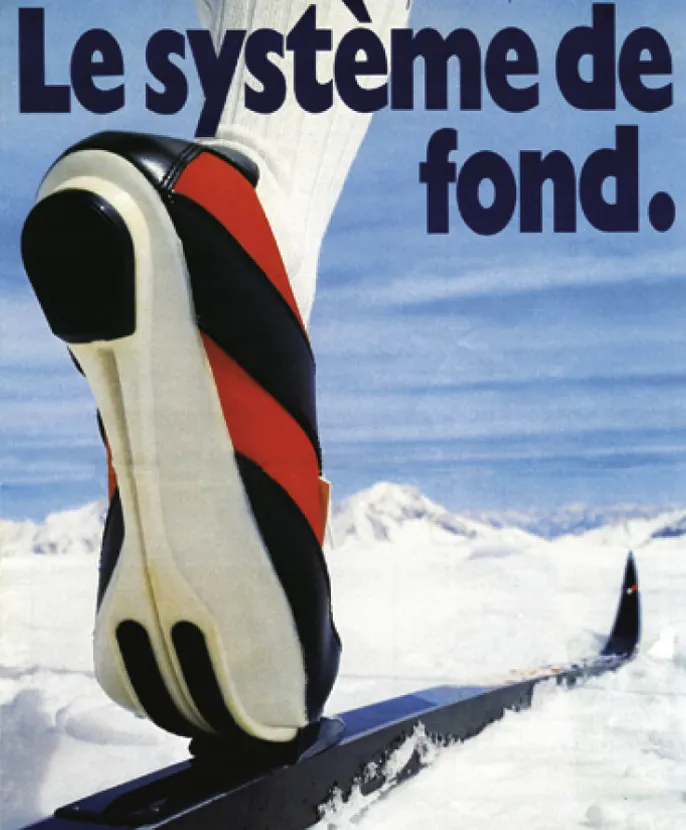

1980- Launch of the SNS (Système Nordique Salomon), a revolutionary boot & binding system

The first models, with a highly original design, are sold in France and Sweden. Salomon becomes the world leader for this equipment in just three years. The SNS is based on a new concept that aims to incorporate flex into the binding rather than into the boot. The company opens a Japanese subsidiary. Salomon records sales of 329,183,000 Francs despite having gone into debt to develop its ski boots.

1990- Salomon launches its first ski, the S9000

Salomon started planning for ski production in 1984, and invested 350 million francs to build an ultra-modern, automated plant in Rumilly, Haute-Savoie, in order to develop their new ski segment. Salomon had not adopted the most widely used “sandwich” structure (where the components are layered on top of each other, embedded in resin and then pressed). Instead, the new S9000 arrives with a monocoque structure designed as a fiberglass “self-supporting beam”, which should ensure improved adhesion, and is made without using solvents.

1992- Launch of the Adventure range of hiking boots

The Adventure range is launched in spring 1992. It is a huge success. A New York Times article is entitled: “Hiking into the future with a lighter boot.” That same year, Salomon is the most successful manufacturer at the Albertville Olympic Games, providing equipment to legends like Edgar Grospiron. The Integral ski boot is designed in collaboration with the great champion Ingemar Stenmark.

1997- Launch of the Salomon Snowboard

After a pre-marketing phase with 3,000 units in 1996, Salomon launched a full range of boards, boots and clothing (under the Bonfire brand). The company relies on its expertise of the “foot-transmission” element to bring real innovation to snowboard boots and bindings. The success and the philosophy of the new department (“Be serious, have fun”) inspires the rest of the company, so the “rounded” logo created for the snowboard market will be carried over into the brand’s general communication.

1997- Teneighty: first freestyle new school successs

Contacted by former Canadian mogul skiers, Salomon took up the challenge of designing the first twintip ski dedicated to new school freestyle… an emerging discipline inspired by snowboarding as well as freestyle skiing (bumps and accro). This emblematic orange model became its first commercial success.

1997- Launch of inline skating

The launch of inline skating is the expression of a know-how at Salomon: that of starting from scratch to launch a diversification and make it a success within 2 or 3 years, just like for skiing. Salomon applies its skiing culture to the industry, and develops innova-tive frames to transmit energy from the foot to the wheels and also introduces speed lacing with quicklace.

1997- XA PRO: a future pinnacle shoe of raid adventure

The XA Pro, a precursor to trail running, is the technical benchmark for multisport raids. Notions of lightness and speed are rising, while the very first model is re-released for the street fashion market.

2002- Kilian Jornet wins the UTMB with an innovative trail running backpack

A thunderclap in the ultra world: an almost unknown young 19-year-old runner broke the UTMB record and won ahead of the discipline’s veterans. It was the start of the fantastic trail running boom of which Kilian Jornet would be the most inspiring symbol. Salomon creates the Skin bag and pioneers the trend of minimal equipment.

2008- Launch of the XT-6 shoe for long distance trails

The historical XT-6 model, very identifiable, graphically strong, was originally designed for long distance trail runs. It then made a surprising breakthrough in the urban field, especially in fashion. At the same time, patented technology “My Custom Fit 3D” revolutionizes instant comfort when entering a ski boot, placing Salomon as the fit leader in the 100 mm segment.

2013- The Advanced Shoe Factory 4.0: a production line “made in France”

Salomon relocates part of the production of its high-end shoes to France. A partnership with supplier SME Chamatex, which specializes in technical textiles, is behind the construction of this production site. One pair per minute will be manufactured on this site operating in 3×8 with around fifty operators.

2021- Tomorrow is yours: Salomon celebrates 75 years of existence and innovations

Tomorrow is Yours refers to Georges Salomon who repeated: “What fascinates me the most is what I’m going to invent tomorrow!” By connecting the heritage of inventiveness and positive openness to the future, Salomon opens the field to draw its next curves, its next paths, and its next adventures.

These brands hold their name proudly as they are all family businesses just like JayJays®. We all love our families and want what’s best for them, sometimes that means creating a family business for a solid income, you also get to spend more time with family despite being at work. For some families, the idea of working alongside each other every day is a nightmare, but with these superb brands including our own, we know how to make it work.

At JayJays® being a family business is our pride, we support each other, understand one another and most of all love the business as if it were a family member. Having these brands that are family run too, shows the unity that can be created through families becoming business allies. We stock these brands as we know they are reliable, just like a family.

Jay Jay’s® was founded in 1993 by our team of former Police and Military personnel. We’ve been manufacturing load-bearing equipment and supplying clothing for the military for thirty years. Our innovative, built-for-life products and industry-leading customer service have earned us an outstanding reputation that we’re incredibly proud of. Why not try for yourself?

Copyright © 2023 Genuine JayJays® Ltd